Packaging plays a crucial role in sterile medical devices fulfilling a wide range of functions. In addition to protecting against environmental influences (physical, chemical, and biological), the packaging also serves to provide important product information. The packaging must ensure the sterility of the product until it is opened and a well thought out design supports the users in this regard. Quality assurance is provided by state-of-the-art equipment and camera systems. We use a variety of different packaging methods which we are constantly improving upon.

Packaging methods

Soft blister

Hard blister

Tyvek® bag

Double blister

Primary and secondary packaging

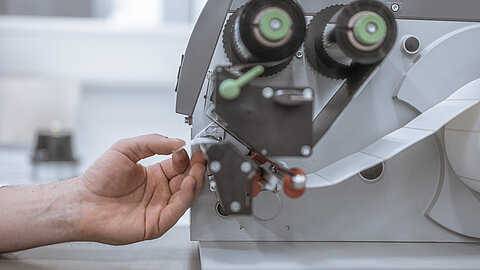

Labeling

UDI marking

Customer-specific instructions for use

Customer-specific packaging design

The packaging area cover 650m of which 120m is class 8 cleanroom. Currently about 25 team members help support the final packaging of our products. The packaging solutions are developed and validated in accordance with ISO 11607.